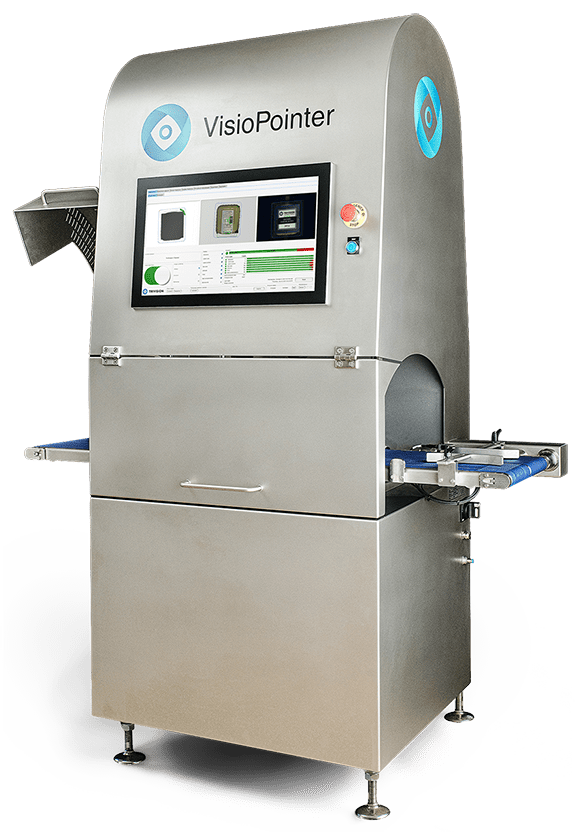

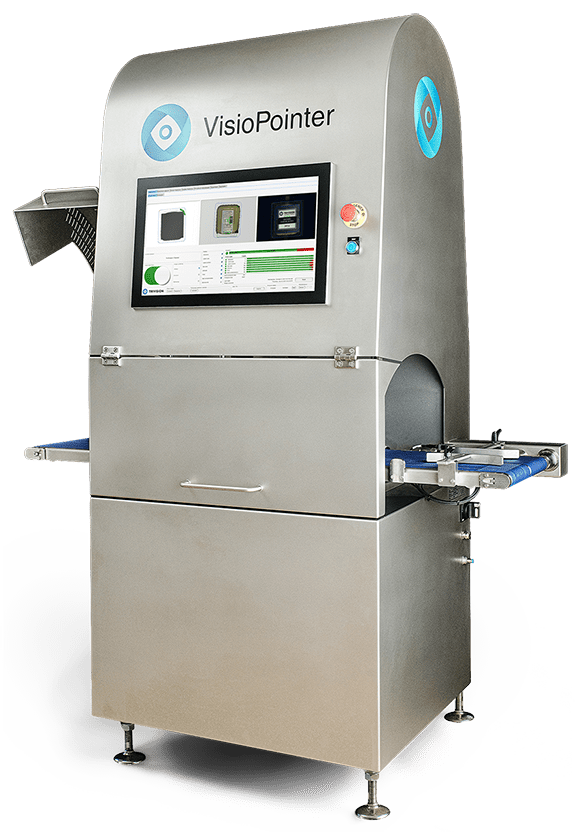

VisioPointer®

A Turnkey Vision Solution

for Thorough Packaging Inspection

VisioPointer® is a high-end, state-of-the-art vision inspection system designed for thorough quality control of food packaging.

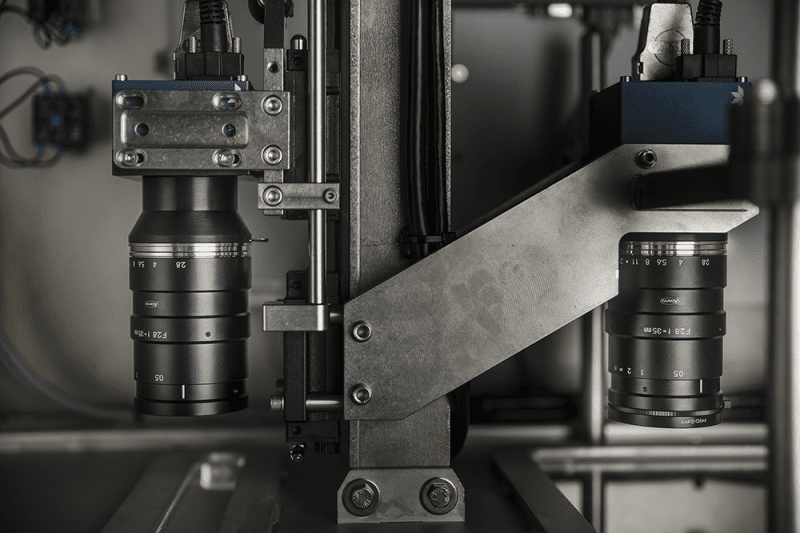

With three built-in cameras, conveyor belt, ejector mechanism and operator panel in its compact body, VisioPointer® is a turnkey solution easy to implement in most food packaging lines.

LEADING VISION TECHNOLOGY

VisioPointer® Boosts

Quality and Efficiency

VisioPointer® efficiently performs thorough quality control of food packaging by inspecting packages reliably at high speed.

Equipped with TriVision's intuitive vision software and data analytics tool, VisioPointer® enables manufacturers to optimize their production by facilitating early error detection and root cause analyses.

Numerous Inspection Types

Available in different configurations with seal, label and artwork, print and barcodes inspection as well as top, bottom and side cameras.

A Compact

Turnkey Solution

A turnkey solution with sensor, camera, lights, built-in conveyor, ejector mechanism and operator panel in one unit.

Intuitivity

Is Efficiency

Powered by TriVision's intuitive software, making it easy for operators to monitor the production and make adjustments.

Highlights

- Automated, complete end-of-line inspection

- Built-in conveyor, ejector mechanism and operator panel

- Intuitive interface for efficient operation

- Powered by TriVision vision software

- Real-time data overview of production performance

- Ideal for the inspection of thermoformed packaging, sealed tray packaging, sealed plastic cup, skin pack

Technical Overview

Specifications

Cameras: GigE Line Scan

Material: Stainless steel AISI 316

Material Encap. parts: Stainless steel AISI 304

Max. conveyor speed: 800 mm/s

Enclosure Rating: IP 64

Ejector Mechanism: Mechanical pusher (Standard)

System Dimensions

Dimensions (excl. shield): 1930H x 1382w x 660D mm

Conveyor Dimensions: 1400W x 300D mm

Max. dimensions of inspected products: 110H x 280W x 350D mm

Conveyor level: 900 mm (+/-50mm)

Built-in Computing System

Processing system: Industrial PC

Operating System: Windows 10 IOT Enterprise LTSB

Interface: Gigabit Ethernet and Digital I/O

Communication protocol: OPC UA and REST

HMI: 21,5" full HD multi-touch panel

Language: All languages are available

Supply

Voltage: 230VAC / 50 Hz, Max 13A

Power: 2,5 kW

Pneumatic: 8-10 bar

Download Visiopointer brochure

Case Story

Heemskerk fresh and easy

VisioPointer® ensures superior quality in Heemskerk fresh and easy's packaging and facilitates optimization in the Company's production.