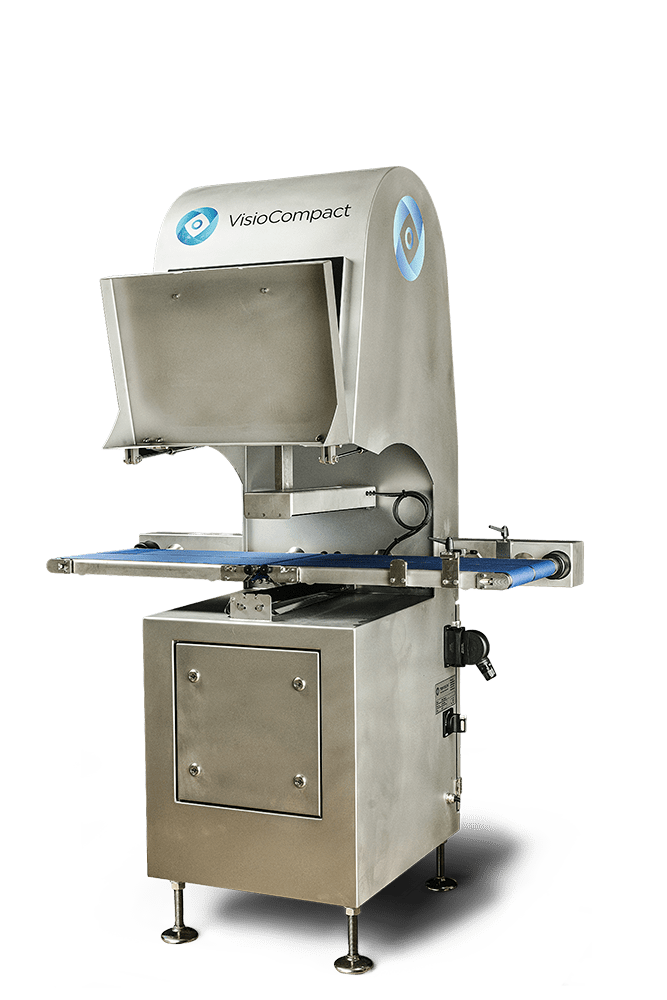

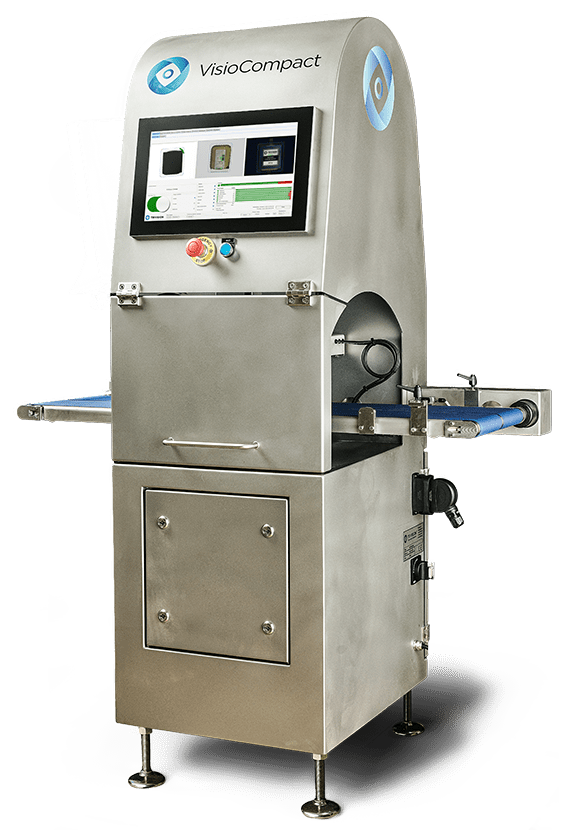

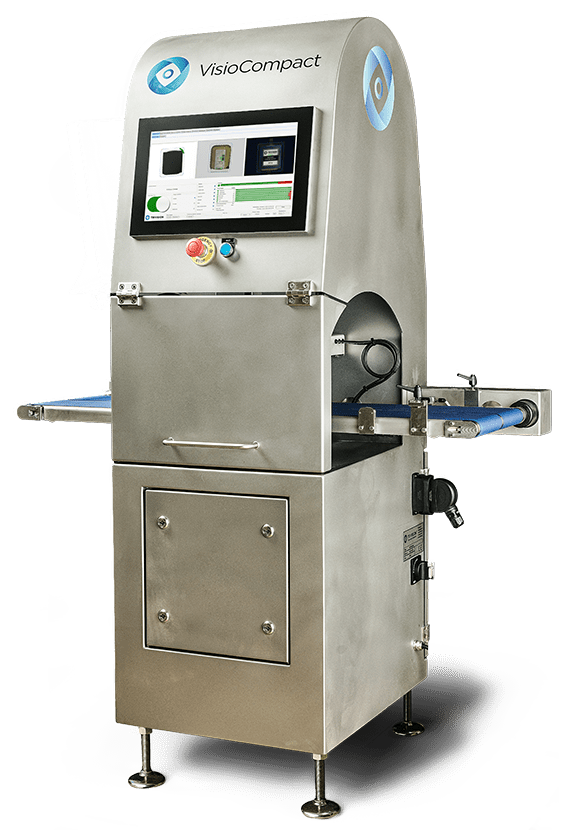

VisioCompact®

A Complete, Compact

Machine Vision Solution

VisioCompact® is stand-alone unit able to perform reliable inspection of packaging within a small footprint. It is the perfect solution for inspecting labels and artwork, barcodes and print on all sides of packaging.

The system can also inspect package seals not requiring transillumination, i.e. packages with non-transparent bottom foil.

Highlights

- Compact stand-alone unit

- Built-in conveyor, ejector mechanism and operator panel

- Powered by TriVision vision software

Technical Overview

Specifications

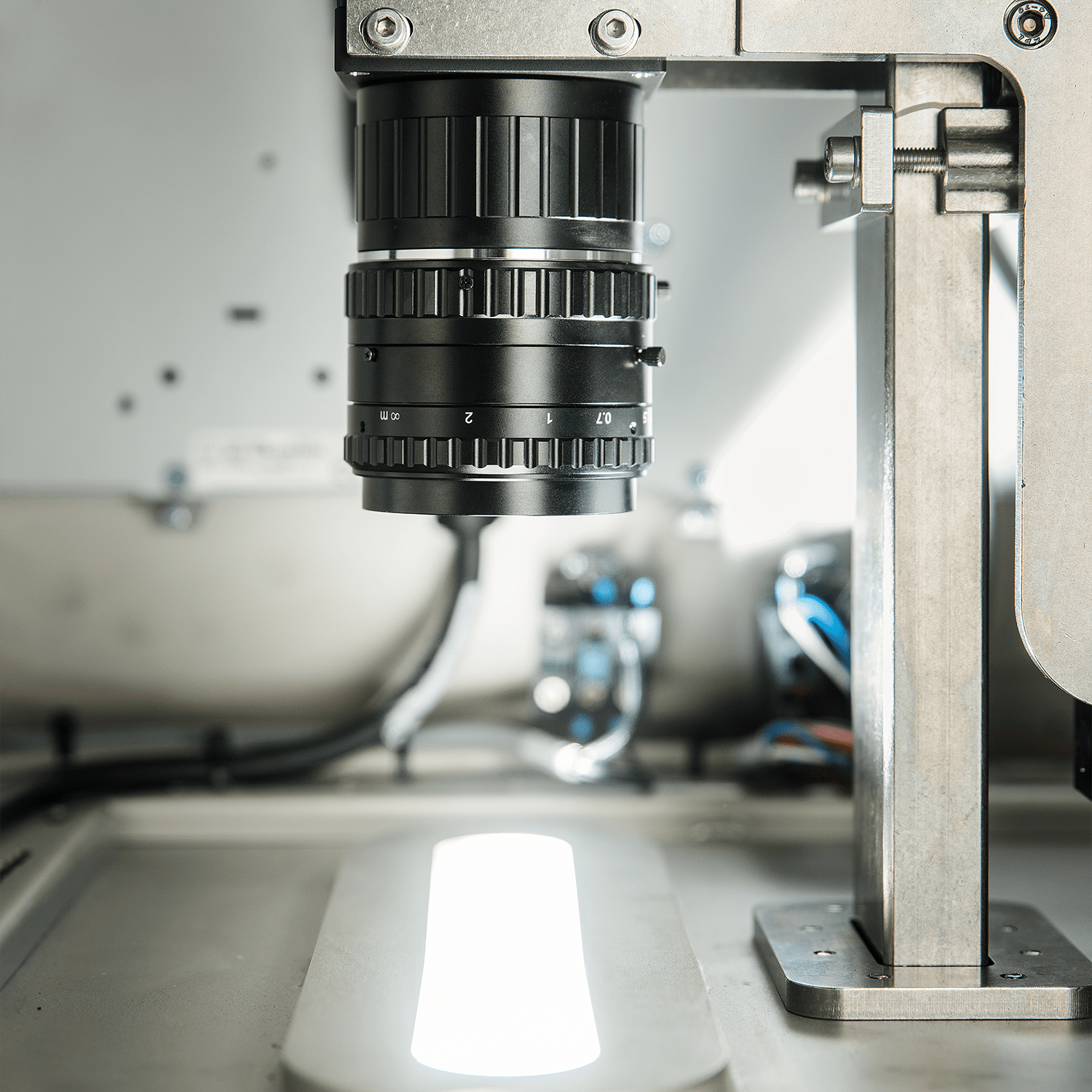

Cameras: GigE Line Scan

Max. dimensions of inspected products: 100H x 280W x 280D mm

Max. conveyor speed: 800 mm/s

Mechanical Specifications

Material: Stainless steel AISI 316

Dimensions: 1680H x 1128W/808W x 610D mm

Conveyor Dimensions: 1128W/808W x 300D mm

Conveyor level: 900 mm (+/-50mm)

Ejector Mechanism: Mechanical pusher (Standard)

Enclosure Rating: IP 64

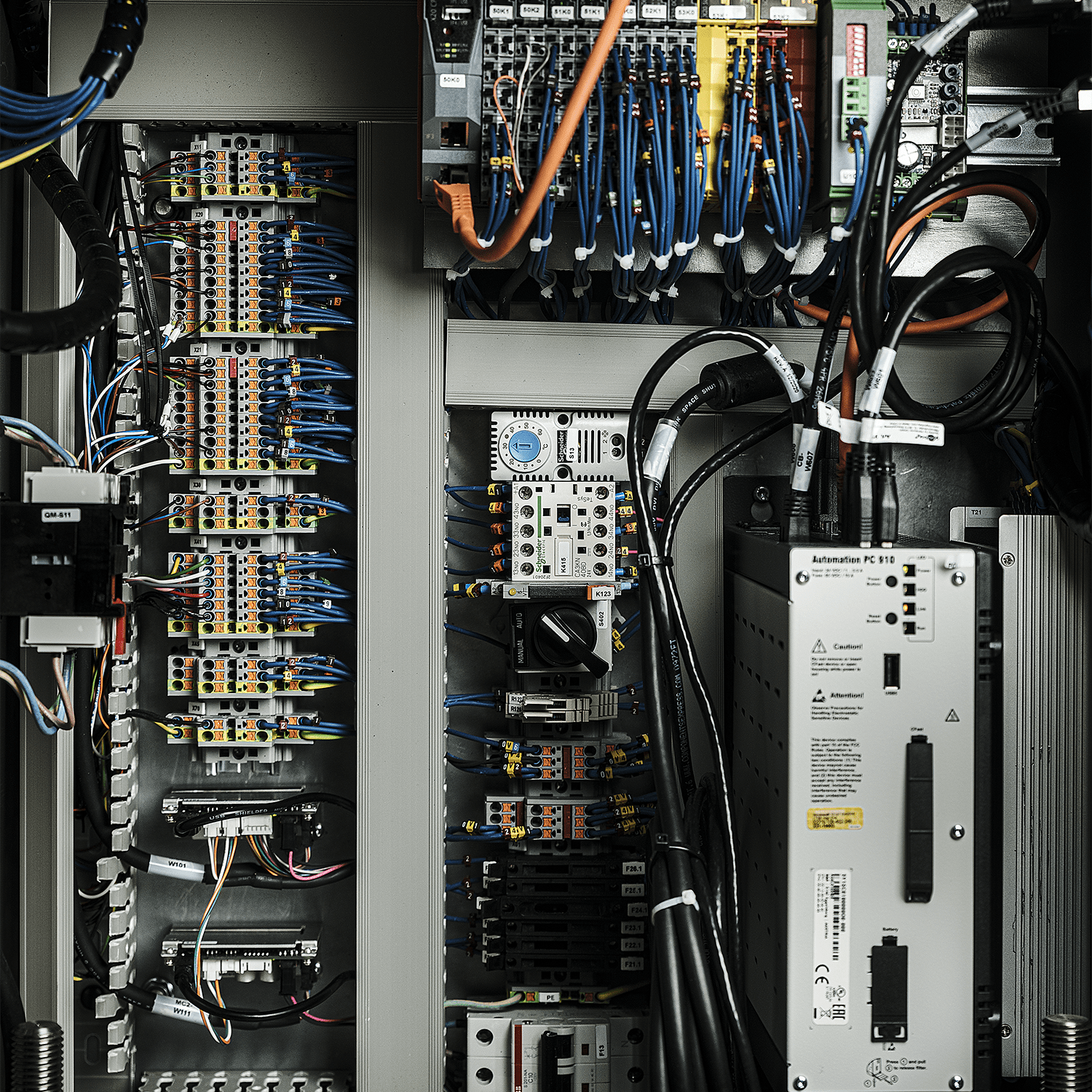

Built-in Computing System

Processing system: Industrial PC

Operating System: Windows 10 IOT Enterprise LTSB

Interface: Gigabit Ethernet and Digital I/O

Communication protocol: OPC UA and REST

HMI: 15,5" full HD multi-touch panel

Language: All languages are available

Supply

Voltage: 230VAC / 50 Hz, Max 13A

Power: 2,5 kW

Download Visiocompact brochure

VisioCompact®

Efficient Vision Made Compact

VisioCompact is designed as a complete vision solution with a built-in operator panel and conveyor, with the possibility for adding an ejector.

With camera setups above and below conveyor level and different configurations available in a clever design, VisioCompact® is truly a comprehensive solution in a compact unit.