Product Inspection with Wide Application

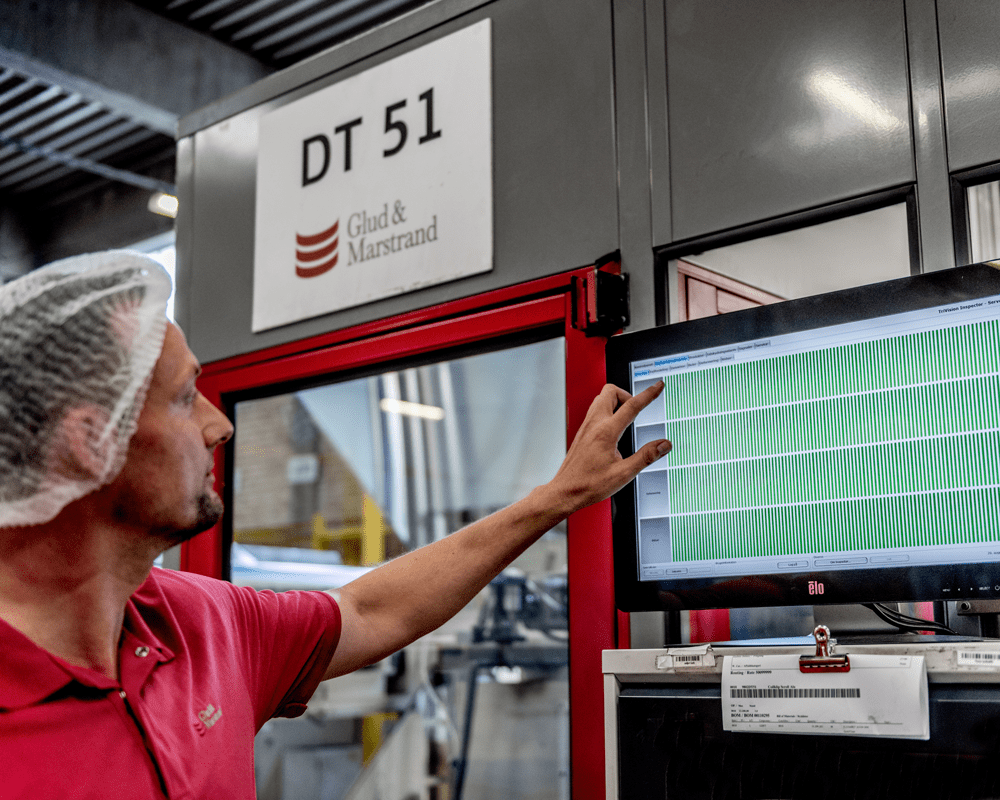

TriVision’s food inspection systems inspect different aspects of different foods as our technology has a wide application when it comes to food inspection. Hence, our systems work as efficient quality control solutions for many sectors within the food industry such as seafood, dairy, meats, prepared foods, and confectionary.

The wide application of our systems also means that we can inspect specifically what is important to manufacturers and their customers. Besides ensuring that all bad food products are rejected from the processing line, our systems' allow manufacturers to obtain data and learn from all inspections made to optimize the processing.

Gain Insights About the Food Processing if Food Quality drops

Knowing what went wrong when bad products were produced is essential in production optimization. Besides inspecting all products and rejecting the bad ones, TriVision's systems also generates data on all inspections to provide in-depth statistics on the production.

Hence, site management can gain insights about the food processing when bad and good products are produced.

The valuable insights from TriVision's production intelligence help manufacturers produce less bad food products and reduce costs.

In some cases, data can also help increasing food quality, even if it already is of an acceptable, high standard.

Earn Customer Loyalty with Consistent Food Quality

Having loyal customers buying one’s food products repeatedly is the dream for all food manufacturers. But having loyal customers requires a high consistency in food quality. Consumers will become loyal customers if they prefer a specific product and expect it to have the same content, appearance and taste at every purchase.

Automated quality control for food inspection is key in ensuring a consistent level in food quality and improving business performance.

If consumers purchase the same food products repeatedly, retailers will continously allocate shelf space for the products. With TriVision’s reliable vision inspection systems, manufacturers can consistently deliver products of high quality, leading to customer loyalty.

However, food quality can be many things as it depends on the specific food product. What consumers find important differs from product to product. Hence, food manufacturers have specific needs when it comes to automated inspection of food products.