How Vision Turns Quality Assurance Profitable

Quality assurance is an important process for food manufacturers as it protects brand reputation, sales, and profits. From recalls, fines and sales decline – all potential outcomes if defective products leave the factory.

But even though being perceived as an important process, quality assurance is also perceived as a cost. A cost that does minimize the risk of facing additional costs – but still a cost. And hopefully, it is a cost that can be reduced over time while maintaining the same level of product quality and protection of brand reputation, sales, and profits.

But what if your quality assurance could be more than just a cost needed to maintain an economic status quo? What if your next quality assurance solution also could be an efficient production optimisation tool and a profitable investment?

At TriVision, we have utilized the strengths of our leading machine vision technology to make quality assurance a profitable business case for manufacturers.

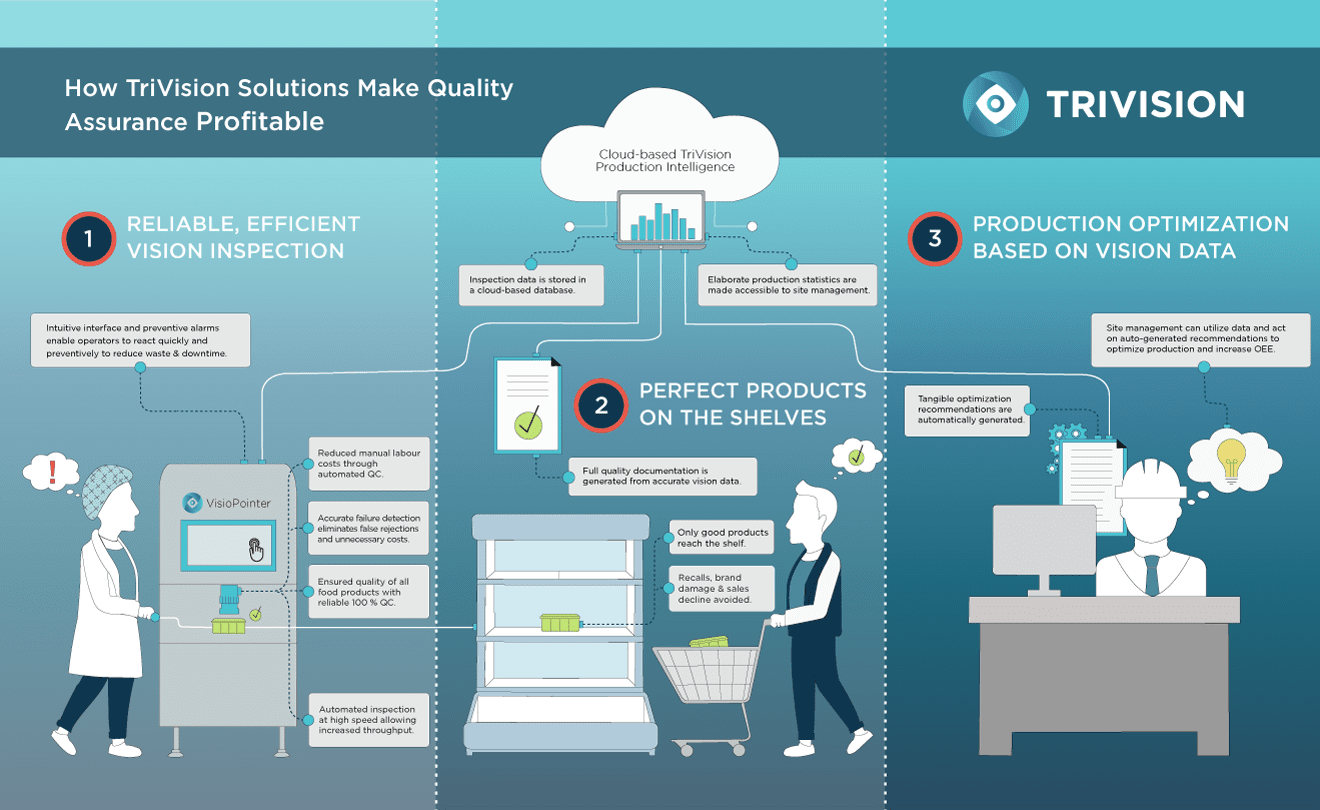

The path towards turning your quality assurance into a truly profitable investment starts with understanding how TriVision systems create value for manufacturers.

Think of a TriVision Vision system not only as an effective quality control system for Quality Managers, but also as an efficient production optimization tool for both Operators and Production Managers.

Discover how TriVision systems significantly improve your OEE

Our vision solutions contain unique features that significantly enhance manufacturers’ business performance. They do so by ensuring quality while reducing quality assurance costs and enabling substantial production optimization.

Dive into our infographic below to discover how a TriVision solution makes quality assurance profitable.

1. Reduce QC costs, unnecessary waste and increase throughput

Efficient, reliable vision inspection

Some of the most obvious costs that our automated inspection reduces are manual labour costs. Based on leading vision technology build on highly advanced algorithms, TriVision systems can reliably perform accurate quality control of all products in high speed productions and hereby release manual labour resources from tasks that increasingly challenge the human eye.

The accurate failure detection eliminates all falsely rejected products. With the ability to set up and accurately follow thresholds for all error types, TriVision systems will only detect and reject products with variations that actually are defined as defective products. As a result, unnecessary food loss, waste and costs will be avoided.

As our automated vision-based quality control can inspect products at high speed, multiple packages per second, operators can maximize the speed of their conveyor belt and overall production to increase throughput and hence OEE while still ensuring complete quality assurance.

A user-friendly system for operators to minimize costs

We have made sure that operators on the shop floor easily can utilize all the valuable data that TriVision systems generate when inspecting each product. The system brings a clear overview of production performance and error distribution with real-time data and sets off immediate alarms if an unacceptable number of defective products appear.

Preventive alarms can also be set up to spot and predict specific tendencies in the production, e.g. if label placement worsens. Based on inspection data and advanced mathematical models, the system can spot and predict if a tendency of e.g. slightly tilted label placements, but still acceptable placements, will worsen and result in unacceptable label placements. If an issue is predicted, the system can preventively alert the operator. This enables the operator to take preventive actions in terms of making adjustments or planning maintenance, before the tendency turns into unacceptable errors that cause food loss, waste, and unplanned stops.

Hence, the preventive alarms improves OEE significantly by reducing food loss, waste and converting unplanned stops into planned maintenance.

2. Avoid expensive recalls and sales decline

The purpose of quality assurance within the food industry is first and foremost to ensure the quality of products that leave the factory to reach supermarket shelves. Whereas quality assurance based on manual labour minimizes the risk of sending out defective food products and packaging, a TriVision system eliminates that risk with reliable inspection of all products and full product quality documentation. A risk that is worth eliminating, as errors in package seals, labels, date markings or appearance can cause bad customer experiences, sales decline, recalls, fines from retailers and in worst case food safety hazards.

Even if manufacturers would choose to reduce conveyor belt speed and decrease productivity to allow manual labour inspection of all products, humans are expected to make mistakes at some point. The number of defective products that will slip through annually and its consequences will vary for each manufacturer.

However, our experiences show us that a TriVision solution is a good business case for most manufacturers using manual labour inspection based solely on how our solution can eliminate the annual average costs of recalls and fines.

3. An efficient production optimization tool based on vision data

Additionally, manufacturers can utilize the generated inspection data further to perform production optimization. Data is generated from all inspections and is converted into elaborate production statistics in TriVision’s cloud-based Production Intelligence data base. As the production statistics are based on accurate vision data, Production Managers can get true, valuable insights into statistics on the overall OEE, uptime, rejected products, error type distribution and cavity error distribution. It allows them to potentially spot trends across various process parameters such as material suppliers or work shifts.

Based on the historic inspection data, our intelligent algorithms and mathematical models, TriVision’s Production Intelligence solutions automatically generate tangible recommendations based on these inspection data, which support managers in spotting the production trends that are profitable to change. Hence, with a TriVision system, site management can always count on having concrete suggestions for optimizing their production.