Intuitive Machine Vision Inspection

Boosting Quality

and Production Efficiency

in the Food Industry

Vision Solutions With Real Impact

Specialized in Vision technology and

the Food Industry

TriVision has supplied the food industry and perfected its machine vision technology for more than 20 years.

Our solutions are designed to make a real impact in food production, supporting producers in ensuring compliance and boosting performance through the provision of reliable, intuitive, and efficient vision inspection systems.

The Many Benefits of Machine Vision

Rely on Automated, reliable QC

Ensure Compliance

Ensure compliance by inspecting all produced products inline and releasing manual labour from challenging inspection tasks.

Utilize TriVision's accurate, reliable solutions based on proven technology to ensure and document the quality of every produced product.

Gather and Utilize Quality Data

Optimize

Automating and digitizing the inspection process allows producers to gain insights on the production performance.

Elaborate production statistics and recommendations can be used to adjust process parameters and boost efficiency.

Minimize Waste, Downtime and QC Costs

Reduce Costs

Machine vision reduces costs in many ways.

Its reliable inspection prevents recall and failure costs, the early detection via 100 % QC and root cause analysis tools minimize waste, rework and downtime, and automating the inspection process reduces QC costs.

Automated Quality Control

Inspect Food and

Packaging From A to Z

We support producers in ensuring product quality, compliance, food safety, and documentation while optimizing - by providing innovative vision solutions for product and packaging inspection.

Case study

Heemskerk fresh and easy

Discover how Heemskerk fresh and easy utilizes TriVision solutions to ensure superior packaging quality for ready meals while running an efficient production.

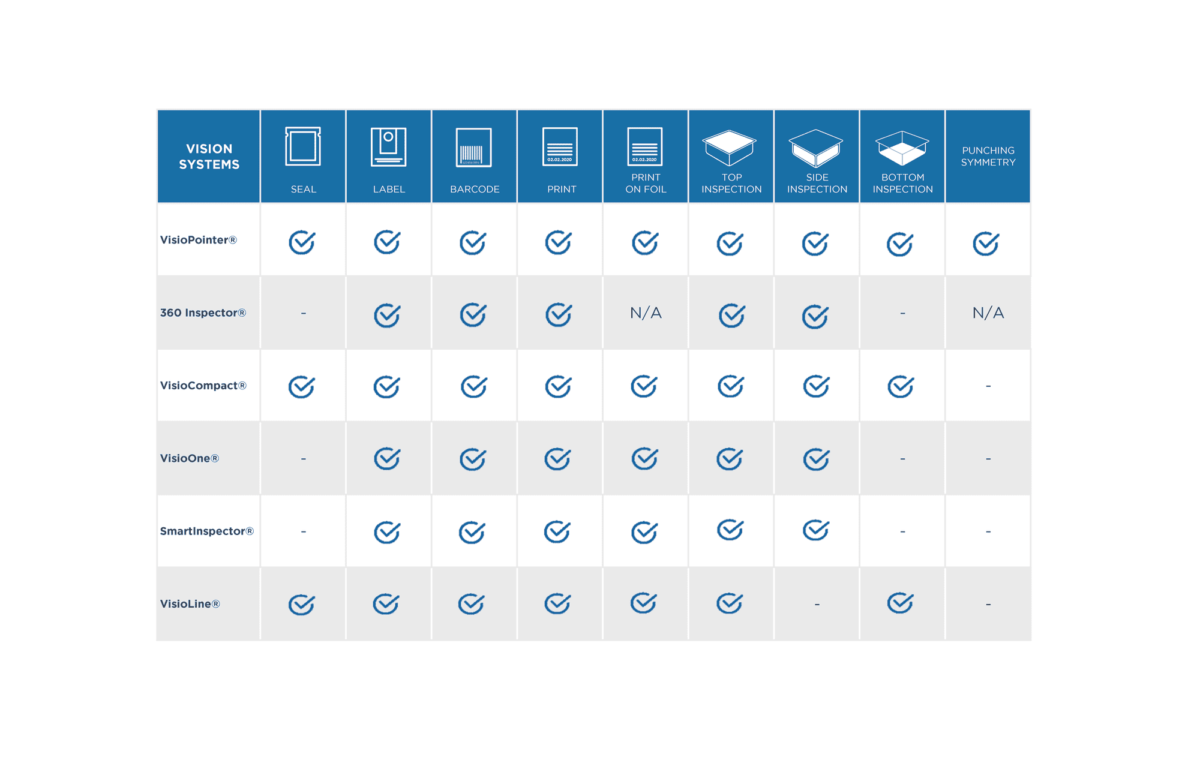

TriVision Solutions

A Range of

Plug-and-Play Solutions

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

The various vision systems offered within TriVision’s product range provide a range of

solutions to cater to the needs of different types of packaging lines and inspection requirements.