Label Inspection

HIGH-SPEED INLINE LABEL VERIFICATION

Verify All Labels

While Maintaining

an Efficient Production

Ensuring correct labeling of all food packages

leaving the factory is crucial to ensure food safety and

comply with regulations. Consumers must be able to identify

the content of a package and allergens must be highlighted

to prevent allergenic hazards.

Labeling errors may occur if applied label rolls

or foil rolls are incorrect, damaged, or placed incorrectly,

which happens if labeling equipment malfunctions

is set incorrectly.

Food labels can be inspected and verified inline

by TriVision solutions right after the label application

and printing process.

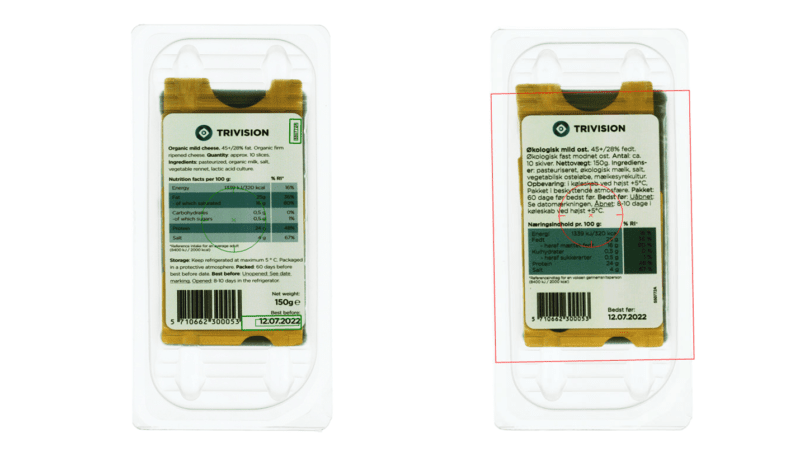

Detect Incorrect

and Missing Labeling

It happens that incorrect label rolls are applied or some packages are missing labels. It can be costly for producers if food packs with incorrect labeling reach the supermarket shelves.

Incorrect labeling can cause severe consequences such as allergenic hazards, which is why retailers want reassurance that all products have correct labeling and comply with regulations.

TriVision solutions help producers validate food labels efficiently to avoid costly recalls and meet retailer demands.

Prevent and Detect

Offset and Rotated Labels

Even if the correct label is applied, label errors such as offset or rotated labels may occur. These errors may occur if the labeling machine is not adjusted properly or if there are issues with the product infeed.

TriVision's vision-based label inspection uses images and qualitative data to discover both errors and trends. Operators will be alerted and enabled to make quick adjustments - to minimize the number of produced errors and even prevent them.

INLINE PRINT INSPECTION

Inspection and Reading

of Printed Markings

Food labels contain variables such as expiry and packing date, weight, and price that are printed inline.

During the inspection and verification of the food label, TriVision solutions also check printed markings to ensure they are correct, correctly placed, and legible.

Discover how TriVision solutions check prints as well without causing the typical false ejections.

ERP & MES INTEGRATION

Verify Valid Label Data

from ERP & MES Systems

TriVision systems are made for smart manufacturing and can be integrated with ERP and MES systems.

This allows producers to automatically push valid label data directly from ERP and MES systems to the vision systems and utilize it during the label verification.

FOOD LABELING DOCUMENTATION

Be a Trustworthy Supplier

With Complete Documentation

Images and quality data are obtained from every inspection performed, which provides complete documentation of all shipped products' labeling and label verification.

Such documentation improves food producers' position towards retailers as they can offer additional value in terms of guaranteeing compliance.

Case story

Norsk Kylling

Read about how Norsk Kylling utilizes TriVision solutions to inspect and validate food labels on chicken products produced in a fully automated factory located in Orkanger.

Solutions for Label Inspection

VisioPointer®

for the most thorough inspection

VisioCompact®

stand-alone solution

SmartInspector®

within a minimal footprint

VisioLine®

for integration into thermoformers

VisioOne®

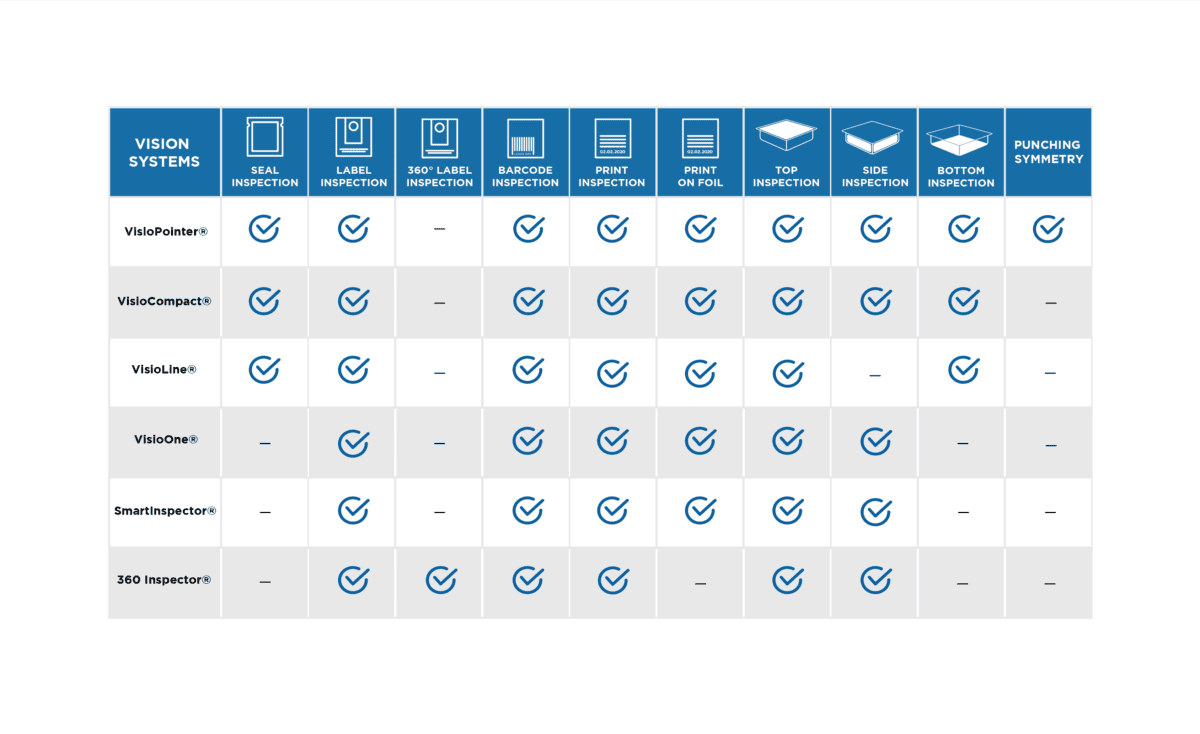

TRIVISION SOLUTIONS

A Range of

Plug-and-Play Solutions

TriVision’s standardized Plug-and-Play solutions for packaging inspection are all built upon the same leading technology and software.

The various vision systems offered within TriVision’s product range provide a range of solutions to cater to the needs of different types of packaging lines and inspection requirements