CASE STORY

Norsk Kylling

Norsk Kylling is a Norwegian manufacturer of poultry products that focuses on product quality, animal welfare and sustainability throughout the whole supply chain. The Company is owned by the international supermarket chain REMA 1000 and sells its poultry products through the brand labels Solvinge and Stange in all REMA 1000 stores in Norway.

In October 2021, Norsk Kylling opened a new, state-of-the-art poultry plant in Orkanger in Norway. This was a massive investment of two billion NOK to boost productivity, quality, sustainability and animal welfare, and a clear signal of being the frontrunner within the poultry industry.

Label Inspection in state-of-the-art packaging lines

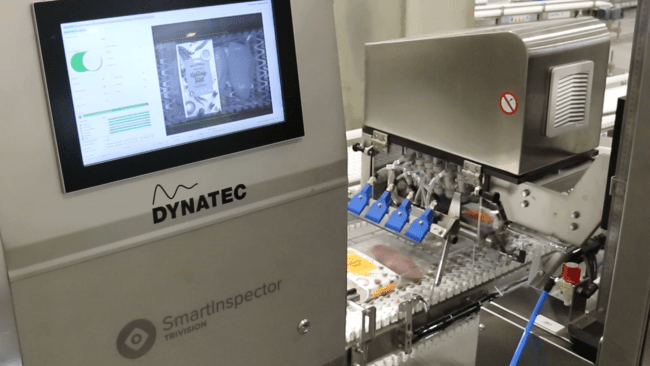

TriVision’s partner Dynatec was chosen to deliver 15 complete packaging lines for the plant, which included providing packaging machines and solutions for labelling, product inspection and palletizing.

To ensure efficient quality control of the labelling in these packaging lines, Dynatec chose to implement SmartInspectors® from TriVision. The vision systems inspect the labelling of both trays and flow packs containing poultry products such as fillets and sausages, ensuring that all products have correct labelling, date markings and barcodes. All products with incorrect or missing information, misplaced labels or unreadable date markings or barcodes are detected and ejected from the packaging line.

The solution had to fit into a modern, fully automated packaging line utilizing the most innovative solutions available. It was a requirement that the system could be efficiently integrated into the manufacturing execution system (MES), facilitating efficient operation through full control of labels, date markings and utilization of quality data.

Equipped with the newest connectivity technologies available, the SmartInspectors® enable Norsk Kylling to fully integrate the product inspection with the MES. This compatibility combined with an efficient quality inspection and HMI made the SmartInspectors® the perfect solution for Norsk Kylling and hence Dynatec.

Efficient solution

and easy to operate

“The customer needed an efficient solution for checking all products and full integration with MES as we were providing fully automated packaging lines for a state-of-the-art factory. The SmartInspector® was able to deliver this while being easy to operate with a nice HMI”

Tore Enes

Sales Engineer at Dynatec A/S

SmartInspector® in action at Norsk Kylling