CASE STORY

Saeby Fish Canners Ltd.

A Need For Automating Inspections of Food Cans

Saeby Fish Canners Ltd. – Europe’s leading manufacturer of canned mackerel – produces more than 100 million cans annually. In 2016, the company needed to update their quality inspection in three production lines to increase production capacity and efficiency.

Having relied on trained specialists who inspected all cans manually, Saeby Fish Canners Ltd. needed to automate their quality control. The company did not want to compromise with its high product quality, and an increased production speed caused by upgraded production lines would become challenging for even the trained human eye.

The required solution had to be able to inspect 360 cans per minute and detect any dents, seam errors, artwork errors, incorrect food labelling and errors in printed date markings. These errors were crucial to detect in order for the Company to maintain its high product quality and ensured food safety.

A High-speed Vision Solution

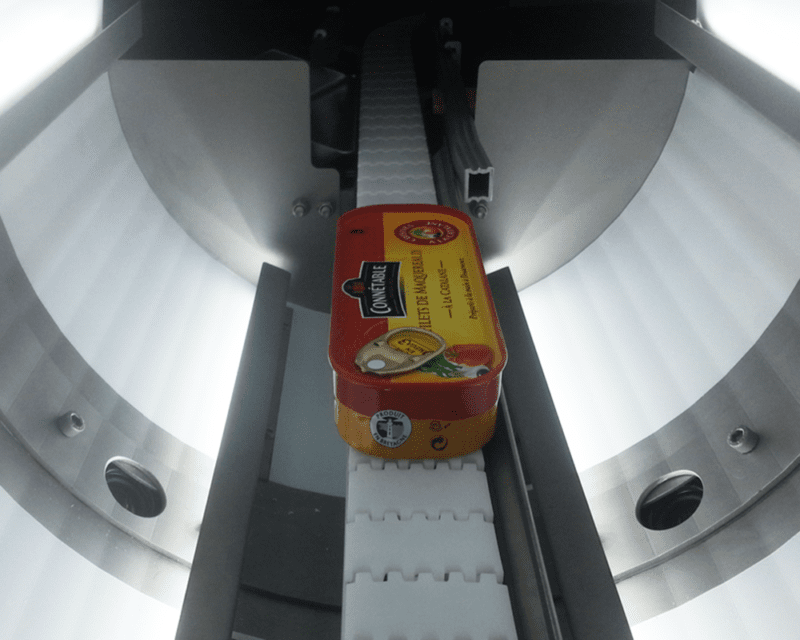

Saeby Fish Canners Ltd. chose to implement three TriVision CanInspectors as the systems were able to meet the tough requirements for a high-speed inspection and provided major benefits.

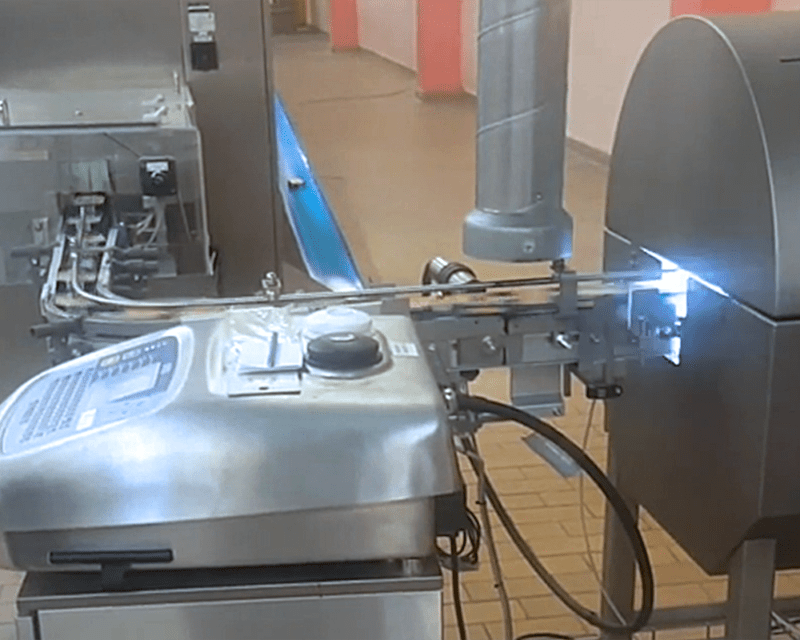

CanInspector® reliably performs high-speed inspection with its ability to inspect 6 cans per second. The system's cameras obtain images from three angles, enabling inspection of cans’ surface, artwork, expiry dates and seam. All faulty products are detected and rejected automatically from the production line by the system’s built-in ejection mechanism.

As CanInspector is powered by TriVision’s intuitive software, the system has eased product changeovers. This was of high value to Saeby Fish Canners Ltd. as the Company has frequent changeovers due to a wide assortment of mackerel in different oils tailored specifically to each market’s local cultures and tastes. Being able to quickly adjust the production equipment, including the vision system, while having frequent product changeovers is extremely valuable for the Company as it kept these processes efficient.

The CanInspectors Have Definitely

Been Worth The Investment

We have maintained our superior product quality while having increased productivity and reduced manual labour costs

Kent Chrisitiansen

Technical Manager at Saeby Fish Canners Ltd.

Key Benefits

- Maintained superior quality while increasing capacity → capacity went from 280 to 360 cans per minute.

- Reduced manual labour costs.

- Reduced training costs – high-speed manual inspection demanded a lot of training.

- Quick product changeovers facilitated by TriVision’s intuitive interface and easy adjustment function

- Cost reduction and production optimization lead to an estimated return on investment of less than 15 months