CanInspector®

Reliable High-speed

Inspection of Food Cans

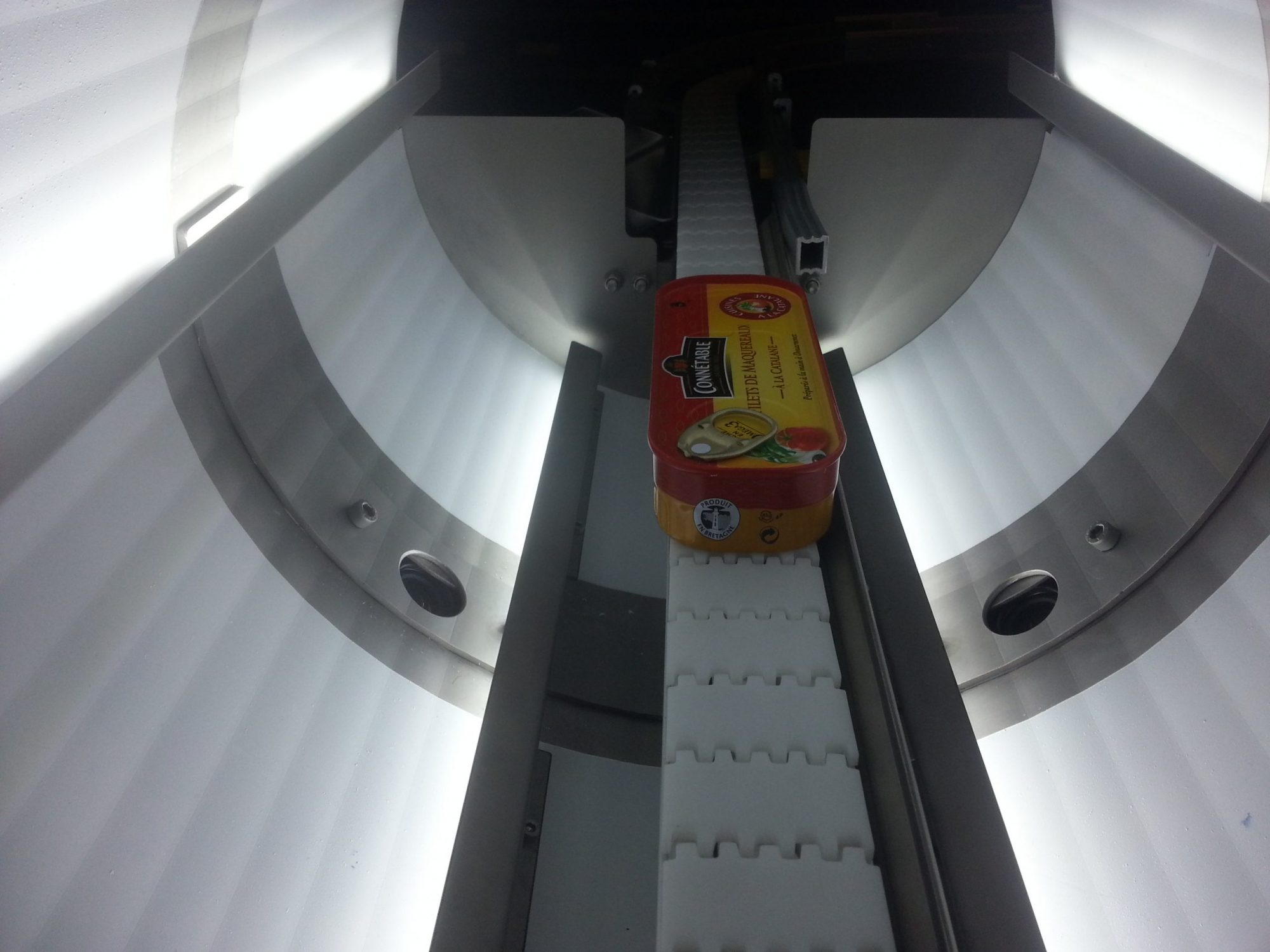

CanInspector® enables producers of canned food to automate the quality control in the canning lines.

Quality inspection of Food cans is challenging as canning lines often run at high speeds.

However, high conveyor speed is no excuse as also food cans must be checked thoroughly to meet the increasing quality demands from retailers and consumers and requirements from legislations.

HIGH-SPEED VISION INSPECTION

Automate Any Inspection

In Any Canning Line

CanInspector® comes in multiple configurations to automate various types of inspections in different food canning lines.

Powered by TriVision's leading vision technology and software, CanInspector® inspects food cans reliably at high speeds and is able to detect any errors in the cans' seam, food labelling, date markings and barcodes as well as dents.

The CanInspectors Have Definitely

Been Worth The Investment

We have maintained our superior product quality while having increased productivity and reduced manual labour costs

Kent Chrisitiansen

Technical Manager at Saeby Fish Canners Ltd.